LTC Prototype Blog

Stay in touch with our blog to get the latest happening around us

Prototype to Pocket: How Vacuum Casting Perfects the Wireless Earbud Case

In the fiercely competitive market for personal audio, wireless earbuds are far more than accessories. It's a compact, critical piece of hardware-a portable charging station, a protective vault, and a statement of design. Its journey from digital blueprint to seamless...

Plastic Injection Molding: The Core Technology in Modern Goggle Manufacturing

From the slopes of the Alps to the lanes of an Olympic pool, from construction sites to virtual reality arcades, the goggles act as a critical interface between the user and their environment. They protect, enhance vision, and enable performance. Behind this...

Unlocking the Potential of LED Lighting with Aluminum Extrusion Technology

In recent years, LED lighting has revolutionized the way we light our homes, offices and outdoor spaces. Its energy efficiency, long life, and versatile design options make it the choice of choice for many applications. A key component that enhances the functionality...

Precision Engineered: The Essential Role of Die Casting in Medical Equipment Manufacturing

The medical device industry operates within an uncompromising standard where accuracy, reliability and sterility are paramount. In this high-stakes environment, manufacturing processes must deliver not only intricate designs but also absolute consistency and material...

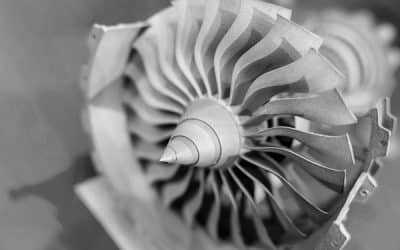

How 3D Printing is Reshaping the Aerospace Industry

The aerospace industry has emerged as one of the first beneficiaries of 3D printing technology, with additive manufacturing fundamentally transforming aircraft design, production and maintenance. This revolutionary approach has enabled breakthroughs that were...

Key Reasons to Use Vacuum Casting for Laptop Keypad Development

When developing laptop keypads, choosing the right prototyping and low-volume manufacturing methods is critical. Vacuum casting stands out for its unique ability to balance cost, speed and unparalleled quality. Here are the compelling reasons to select this process....

Plastic Injection Molding in the Packaging Industry: Precision, Speed, and Versatility

The packaging industry is one of the largest consumers of injection molded plastics. This process is ideal for creating high volume, consistent, and highly functional packaging components that require precision, durability, and superior aesthetics. Injection molding...

The Future of Surface Finishing: A Paradigm Shift Driven by Sustainability Digitalization and Smart Materials

For centuries, surface finishing has been a fundamental final step in manufacturing—a craft meant to protect, beautify, and add functionality. While the core objectives remain, the industry is now at the precipice of its most significant transformation. Driven by the...

The Critical Role of Micro Molding in Minimally Invasive Medicine

In its relentless pursuit of less invasive procedures, smarter drug delivery and more powerful diagnostic tools, the medical industry faces a constant challenge: how to fit more functionality into increasingly smaller spaces. The answer to this challenge often lies...

Complete Guide to Alloy Selection and Optimal Processing Conditions in Pressure Die Casting

Alloy selection determines the success of your pressure die casting project. Aluminum alloys dominate most applications due to their excellent strength-to-weight ratios. Zinc alloys offer superior dimensional accuracy and surface finish. Magnesium provides the...

Vacuum Casting for Small-Batch Luxury Automotive Interiors Cost vs. Quality

Luxury automotive manufacturers face a critical challenge when producing small-batch interior components that demand exceptional quality without the massive investment required for traditional manufacturing methods. Vacuum casting emerges as the optimal solution for...

Vacuum Casting for Medical Wearables: Enhancing Precision and Durability

When developing medical wearables, achieving precision and material compatibility is crucial for ensuring comfort, safety, and optimal functionality. Vacuum casting provides a reliable method for producing detailed prototypes and final parts that meet these demands....