If you are into CNC machining, there are thousands of metals to choose from to handle tasks. Allows are the best options to experiment and put your brand new CNC machines to test. If you are already an experienced user or a business owner, you know the basics to choose materials: you have to be able to work with them on your machines. They have to be durable, resistant, capable to withstand corrosion, and they should look good as well. We will run down a quick list with the best options available in the market so you can get started right away:

· Aluminum 6061

This aluminum grade is probably the most comfortable choice in the list. This is the most basic, all-purpose aluminum grade you can find. It has elements of iron, magnesium, and silicon and iron. It features an exceptional strength-to-weight ratio and is one of the few options to be naturally resistant to corrosion due to natural elements. It’s very easy to handle, and it can be machined pretty easily. You can weld and anodize with it as well.

When it’s heat-treated, the 6061 has higher yield strength than Annealed 6061, but the price is also a bit higher. The only setback we can list is that it loses a great deal of corrosion resistance when is exposed to saltwater and certain chemicals. It’s also not strong enough for demanding applications. This alloy is mostly used to create brand new auto parts, bicycle frames, a few sports goods, aircraft components, and frames for remote-controlled vehicles.

Aluminum 6061 part*

· Aluminum 7075

This is the higher grade of aluminum you will find on the market. It’s alloyed with zinc and is considered one of the most durable aluminum alloys, with the best strength-to-weight features. Because it’s so strong, it can be pretty tricky to handle it. It has average workability at best which of course means that it can spring back to the original shape it had if it’s cold-formed. The good news is that the material can be machined and anodized easily.

The 7075 alloys is usually used to be hardened. Is considered a bad choice for welding, but it works amazingly well to make plastic injection mold tools. This alloy is also used pretty often to manufacture high-strength recreational equipment used on mountain climbing. Big industries such as automotive and aeronautic use the metal reinforce stressed parts on their vehicles.

Aluminum 7075 CNC Milling Machining Part**

· Brass

Brass is a combined alloy of copper and zinc. Is regarded as one of the softest metals you can work with. It can be machined without the need for lubrication. It is pretty workable, even at room temperatures. Is mostly sued for tasks and parts do not require great strength. There are a lot of variations of brass, most of them measured by the amount of zinc contained on them. The more zinc you find on brass, the less corrosion will be on it.

Polished brass can look a lot like gold, that’s why it is used in many cosmetic applications. The metal is really good to conduct electricity, but it’s non-magnetic. It’s also pretty easy to be recycled. It can be used for welding at low-temperature, for brazing or even soldering. Brass never sparks when is struck with other metals, so is safe to use on flammable environments. The metal also has great anti-bacterial, and anti-microbial properties, so it is really easy to clean. Brass is used a lot to create wind-based music instruments.

Brass part***

· Magnesium AZ31

Magnesium AZ31 is an alloy created using aluminum and zinc. Is 40% lighter than aluminum, but it’s as strong as well. The only downside is that it is costly. The metal itself is pretty easy to machine, but it is flammable, so it must be machined using liquid lubricants. Magnesium can be easily anodized as well. It dramatically improves its corrosion capabilities. The metal is incredibly stable to keep structures together, so is ideal for pressure die casting. Magnesium AZ31 is used to create aircraft parts of lightweight, as well as high-strength. It can also be found in housings, power tools, laptop cases, and cameras.

Magnesium alloy cnc machining****

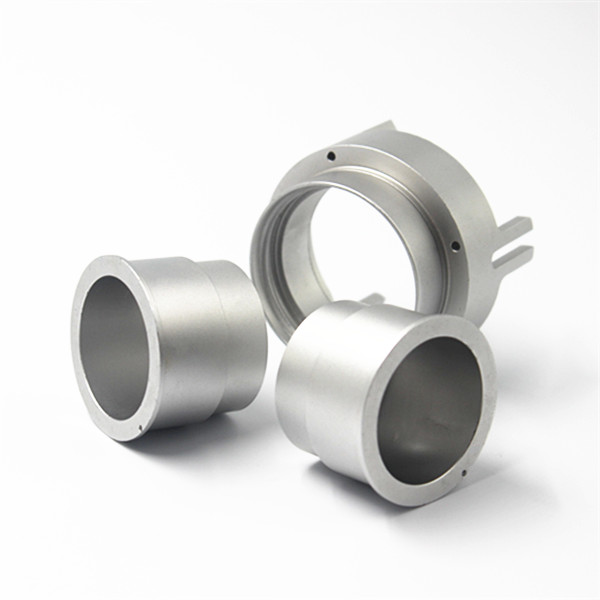

· Stainless Steel 303

There is no such thing as one single type of steel, but all of them certainly look the same to the naked eye. This happens mostly because every steel piece includes chromium to keep them from rusting off. This material is for experienced CNC technicians. They need to be able to pull the tests on the raw material using OES detectors to confirm they have the right one. SS 303 is probably the most machined stainless steel because it’s pretty easy to work with in every regard. This metal is an excellent choice for bending, but it works poorly under the heat. Since this option has a lot of sulfur, it can’t be weld either. SS 303 is mostly used for nuts and bolts, fitting, gears, and shafts.

Stainless steel parts 303*****

Reference

*Image from https://www.coxmanufacturing.com

**Image from http://www.weimi-machining.com

***Image from http://www.acmanufacturing.com

****Image from http://www.mkmockup.com

*****Image from https://www.coxmanufacturing.com