Plastic injection moulding is one of the popularly used plastic formation techniques with several industrial applications. The industry is evolving and expanding continuously. Customized plastic injection components are the best solution for different industries that are working hard to produce a good volume of premium quality and affordable parts.

These plastics are utilized in the production of complex and sophisticated shaped parts. The healthcare industry is considered the fastest-growing segment for the industry. Blood sample analysis cuvettes, pregnancy test kits, housings for needles are only some of the preferred sections since injection-molded plastic is lightweight, easy serializable properties, and cost-effective.

The demand for these kinds of items is increasing, mainly because of the pandemic. Some of the reasons for the rise in popularity of plastic injection moulding include volatility of the used raw materials, international concern on proper disposal, and government support through tax benefits. The value of the injection molded plastics market size is around $258.2 billion last year. This year it was projected that it would grow even further. Below are some of the trends that are increasing in the steady progress of the plastic injection moulding industry.

High-Performance Materials

The latest trends in plastic injection moulding makers are the use of temperature resistant and corrosion-free materials. An example of this is in the automotive industry were using these types of materials is the best way to boost the durability of the components. It also lowers the weight of different parts of the finished product to improve the fuel efficiency of the produced automobile. For every 10% reduction in weight of the vehicle will result in a 5-7% reduction in fuel consumption.

Also, the use of the eco-conscious plastics continues to achieve traction in the market since they manufacture lower level of effects on the environment. Some of the popularly used plastic materials in this sector are polypropylene, PVC, and polyurethane.

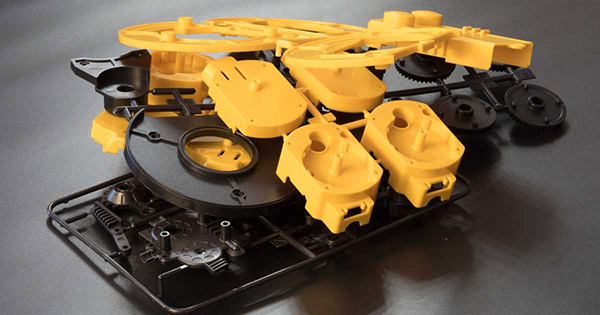

plastic injection molding parts*

Recyclable Plastic Waste

Rather than recycling the plastic in their land, the USA, as well as other developed countries, send their plastic waste to China. Around 106 million metric tons of plastics are being exported to China. But, in 2018, China banned plastic waste importation due to environmental policies and the dangerous effects on the health of the people. Now it is a trend for manufacturers to have a responsible recycling plan for plastic waste in an eco-friendly way.

More extensive Application of Reinforced Plastics

As it usually shows high strength and low weight, the plastic composites usage is getting popular for plastic injection moulding makers in 2021. Generally, fibers are injected into plastics include materials like carbon-based fiber, aramid, and glass. The industries benefiting from the use of reinforced plastic products include construction, nanomaterials, automotive, power, and a lot more.

The utilization of such materials in manufacturing is quite a welcoming trend because it reduces the per-product costs that maintain the required component strength. In industries such as aerospace and automotive, the reduction of component weight may increase the value of the end-products through improved aerodynamics and better fuel economy.

Final Words

The only constant thing on earth is change, so the industry will continue to improve with better technology, finer material specifications, and environmental conditions. Keep in mind the benefits of technology and the latest trends. It will not take a lot of time before you start implementing plastic injection moulding in your industry.

Reference

*Image from https://www.sofeast.com/