The booming economies all over the world have given rise to a lot of new inventions. People and companies are developing new products. This demand in research and development has created a gap that is costly and takes considerable time.

What we are talking about are the ineffective steps of modeling, prototyping, and testing. Sometimes, it takes more than one cycle before getting the perfect product. Luckily, there is a time-saving process that is helping design and development. We are talking about the computer-aided process known as CNC machining.

This technology has created a wave of change in every industry and opened new doors for simple inventors and big companies.

CNC Machining Took Over Traditional Milling

CNC machining uses the computer to convert the numerical values of any design into commands to control its cutting into the material. These numbers act like coordinates for the cutter to work along the X, Y, and Z axes.

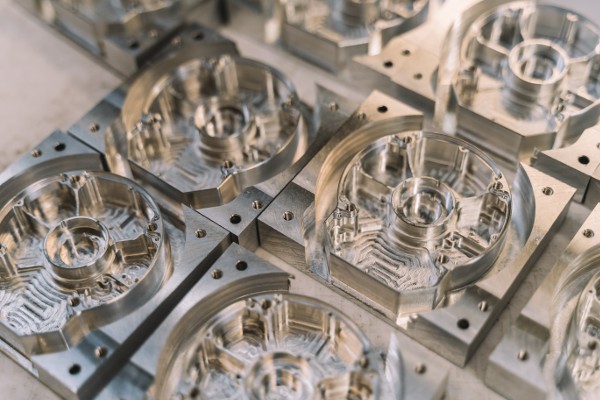

Compared to 3D printing, the process in CNC milling removes the material from the block until the desired piece is achieved. It’s like a sculpture only made by a computer.

Among the types of CNC machining, CNC milling is the most popular due to its versatility. It can perform turning and drilling functions and aside from the three CNC axis, it also has more axes including the Milling Head Z, and the pivot and angles for more flexibility.

High precision CNC Machining*

CNC Machining on Metal and Plastic Prototyping

CNC is not another technological trend or a marketing ploy. It has many applications in different industries including medical, transportation, defense, aerospace, and many others. It also has helped in plastic and rapid prototyping and is popular in producing plastic and metal parts in many quantities.

This capability of CNC machining enables inventors and designers. Even the genius tinkering in the basement to the largest companies in the world can benefit.

Another advantage of CNC machining is its testability. The produced parts can be tested for their usability or functionality. The process of CNC itself involves a stage known as cutting air, with a trial run is done to test the program before the actual production commences. This process eliminates errors and potential issues.

CNC machining has higher precision than traditional machining. It allows for unlimited repetitions with the same properties, and every part made is identical to the rest. The process is also capable of accommodating even the most complex geometries which manual machining cannot do.

Most companies use the CNC to create demonstration pieces for stakeholders. Especially when they are looking for proof-of-concept during the presentation of products for development.

What makes CNC machining a top choice in the manufacturing process is its increase in productivity. It reduces the time because the machine changes tools without intervention. It also uses a high-pressure coolant that minimizes the heat in the cutting zone and clears away the debris and chips away.

There are other manufacturing options for product designers to choose from, but CNC machining tops it all. It has modernized the approach to product design and development.

Reference

*Image from https://www.protonautics.com/