If you have some understanding of plastic injection molding procedures, you probably know that computer-aided design is an essential part of any manufacturing project. Also known as CAD, this form of design has become a staple of the industry and something that can be created using multiple computer software out there. One of the most famous programs is AutoCAD, and while it is still popular, a lot of companies go the customized route to be able to handle the most intricate designs

Learning to manage CAD software can prove to be challenging if you are a newcomer in the field. This is why experienced designers in manufacturing workshops are the ones trained to handle these programs correctly. While you may have a vision about your part or product, CAD designers are the ones with the expertise to take your ideas and lay them out in digital for you to see. By creating a visual notion of your ideas, you will be able to analyze if it works, or see if there is room for improvement. Most manufacturers can take the work of other workshops to improve it.

One of the most common obstacles faced by newcomers to CAD is the number of file extensions available. Native files are always great in their own ecosystem, but if you need to run them on a different program, you will have to convert them. Importing a file always carries a lot of complications, but it can be done. The natural drawback of such a drastic change is the disruption of the file. This used to be a fairly common occurrence until some time ago. The main issue these days is time, one of the most valuable currencies in any manufacturing project.

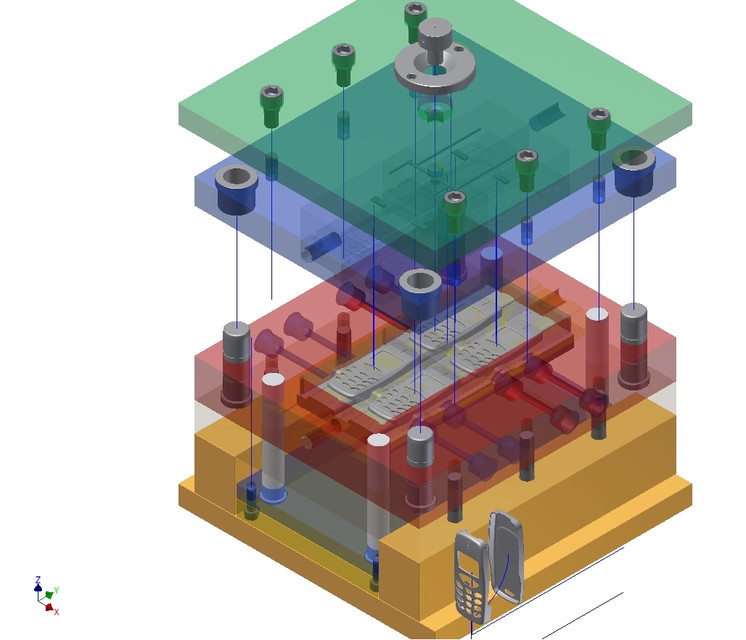

mobile phone 3D CAD models*

Working Your Way Around CAD File Formats

Understanding CAD files is not that difficult if you separate them into two basic categories. The first one is called solid bodies, and the second one is named mesh bodies. They both are very different, but they have particular traits to them. We are going to discuss these differences briefly:

ü Solid-Body Files

A solid body file is essentially a 3D image that allows you to inspect the whole design in one of the most in-depth fashions. You can see the entire shape of the construct in a computer-generated representation of how will actually look like when it goes to a production cycle. The files are commonly used in workshops. They are used to evaluate the feasibility of the project and to understand how the part works. It’s also a great barometer to calculate expenses and measure physical traits such as weight, height, and density. The most popular solid file extensions are listed below:

-

SLDPRT

One of the most common file extensions and the one usually run by trial-free AutoCAD software. It allows a lot of customization, but the files can’t be locked.

-

STP

This is probably the most universal standard among CAD files. STP files rarely need conversions, most CAD programs accept them, and they are compatible with ISO files. You may remove proprietary design features on older files, but they are very tricky to edit.

-

IGS

IGS is known for being compatible with every single type of CAD software out there. The structure of these files is very much like STP, but it’s easier to work with, and it can be edited without having to endure the hardships of the older format. They are known for being the easiest format to share.

-

Mesh Files

The graphic framework of mesh files is 3D modeling as well, but this type of file works very differently to solid body files. All the models created in this environment are composed of polygons. Each one of them represents the outer layers of the products being designed. The file can be broken in all the data points that are necessary to make the construct and connect them using the polygon shapes to get a better view of the internal parts of the construct. They are incredibly detailed, but they take a lot of time to create or edit. These are the most popular mesh file extensions:

-

STL

This is the most popular format used for 3D modeling and rapid prototyping. They are best suited to create hollow pieces.

-

OBJ

This is probably one of the most complete types of files you can use to get a full look at your part before creating it. It’s one of the best tools for examinations and previews, but no one will ever recommend you handling this format to create our product since it’s probably one of the most difficult files to edit.

What is the Best Format to Handle Your Project?

The question has endless layers of consideration. Still, we can narrow it down to a fundamental notion: use the file that increases the efficiency of your manufacturer while keeping the costs low. This doesn’t mean that you have to go the cheap route or create low-quality products. Most manufacturers will advise the best file extension for your project based on these notions, but they are willing to go the extra mile if you plan to disrupt the market you are targeting with your plastic injection molding project.

Reference

*Image from https://grabcad.com/