To give you a good insight into the complexity of this technology, let’s say that the time frame required actually to learn what you need about it is offered in the equivalent of a college semester. It all begins with the basic commands we program in our head that will eventually manifest through the control of the CNC machine to become in the movement of a linear axis.

The Physical Task of the Future

As operators, we manage a program that is either conversational or delivered using G-code, a programming code. We use any of these methods to provide commands in the form of a list. The commands are organized by the CNC control and arranged in categories for every single ax of the machine. After they are passed along through the circuitry, a nudge of voltage will make the axis move to do what it has been commanded. The whole process takes a fraction of seconds.

As the axis moves to do the CNC machining task, the position of the device is monitored using an encoder placed at the end of the motorized parts. The monitor also provides all the feedback needed to the drives to make the necessary adjustments and make the motors work faster, avoid lagging, and adjust the voltage of every movement to make the spin faster or slower depending on the needs of the CAD model. Keep in mind that this is a work of precision.

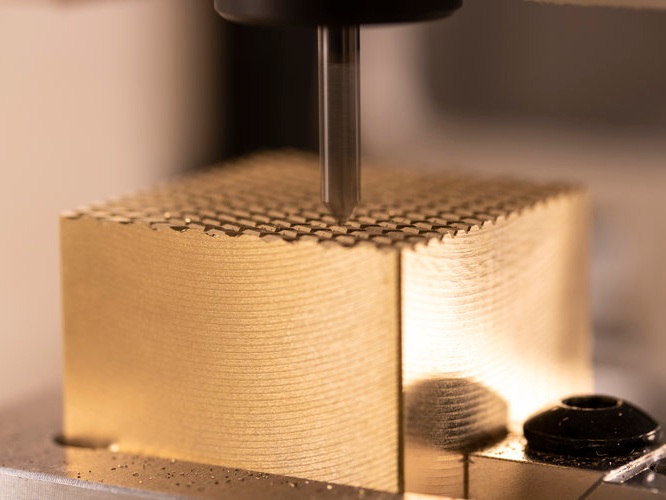

Brass knurling desktop CNC bantam tools*

Overshooting the Axis Motions

We mentioned analogies when it came to the full explanation CNC motion control systems. Let’s compare this CNC machining method with driving a vehicle. Your first command will put in the road. Your goal is to travel to a final destination, which is nothing else but the material you are working with. What you drive is the tool, and the cutters trace your path. In the same vein of driving, you must pay attention to your reflexes and react to avoid going too fast.

As your body suddenly equals a driver’s seat, you will realize how your extremities work to control every ax of the CNC machine, the same way to do it with a vehicle with all the pedals, levers, and the wheel. This requires a lot of practice, especially if you have to picture a narrow road. The best you can do is use the largest image you can get of a path that is ideal for you and work your way on it. It would be best if you kept a lot of attention on your eyes since they are the ones that speed up the procedure with entry-level motion control systems.

Building the Road as You Go Through it

Most of the trick with this type of CNC machining method is fining a smooth trajectory that helps you keep a steady pace as you place every command. While there is a lot of innovation here, motion control systems are still pretty inexact. They can achieve awe-inspiring work, but it needs mastery. Your brain will often react to any outside stimulation, and the machine will fire back with feedback reactions interrupting the task.

After a great deal of practice, you will be able to handle elevation changes, decreases of pressure, and precise placement of commands. If you feel skeptical about it or the notions result confusing to you, keep in mind that motion control manufacturing is not a mental process. It’s a physical one, and all the advice we offered is centered on having the best possible control you can achieve with your mind over your body.

Closing Thoughts

CNC machining based on motion control requires you to block and look ahead as you manage any task. The blocking part refers to the set of spaces you need to control this process in a viable manner. CNC motion control has an incredible amount of digital backup, but it does no good at all if we can’t control our memory reactions. You look ahead to trace the next movement as you finish one. This can sound excruciating, but according to the experts, it becomes a muscular reflex once you train your body to it.

There is probably a lot more to say in this regard, but speaking about this technology in this space is only to make you aware of its existence and to look forward to its use for very intricate machining tasks in the future. The technology is already here. It is safe to say that it only needs a tune-up and our full commitment to learning how to use it appropriately.

Reference

*Image from https://www.bantamtools.com/