Milling is one of the most common mechanical tasks performed on various workpieces. It involves a tool to cut, turn, sharpen, smooth a surface, drill, etc. It is at least used once in every type of structure made. It is a versatile machine and is a part and parcel of every shop that works on materials like plastic, wood, steel, etc. A technically more advance and a new generation milling machine is the CNC milling machine.

What are CNC Milling Machines?

A CNC machine stands for a computerized numeric control machine. It is a machine that works the mechanical actions as per the numeric codes provided to it via an algorithm. It feeds on numbers to let it know how long or deep or wide the function is to be performed. With the same tools and machine size, they come along with CAD reading software, a conversion tool from CAD to CNC and other mechanical equipment. It still requires the human hands to feed in the workpiece and change the tools as needed. It only reduces the task of taking repeated measures which in itself is a tedious procedure.

Benefits of the Shift

So does the shift from traditional to CNC milling beneficial? Of course, it is for the following reasons:

- A CNC machine reading is based on the computerized number is more accurate than the scale or inch tape read by the humans.

- It is a highly reliable process that provides for a replica of the CAD image that got converted into the CNC code.

- It provides for exact measurement with not even a slight difference in the dimensions and therefore is very precise.

- It consists of the major part being covered by automated machines and therefore reduces human tasks and efforts.

- It is a one-time investment and is pocket friendly for everyone who wishes to start a new business or task with CNC milling machines.

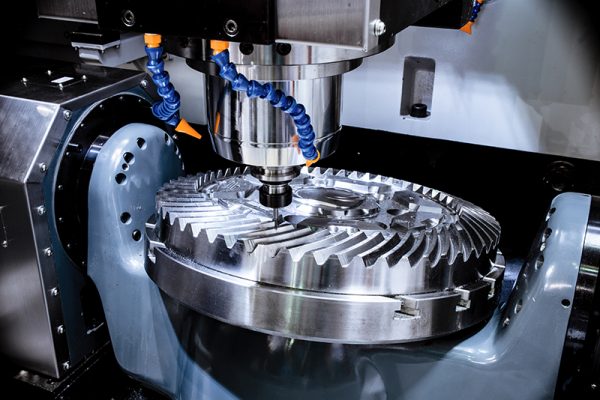

A modern CNC milling machine makes a large cogwheel*

How Does it Work?

The process of CNC machine consists of four important steps:

- The first and step are to design and create a CAD model either 2D or 3D. Greater the dimensions, the greater will be the accuracy and the finish.

- This CAD design is then made in CNC readable format by using a converter and is fed into the CNC machine for making the numeric feed in the algorithm.

- Preparing the machine by fixing the workpiece and choosing the right tool for the operation to be performed.

- The execution of the operation takes place as per the required and fed dimensions in the CNC milling machines.

The transition of milling machines into CNC machines is a boon to every person who struggles to create a replica of the same dimensions as required for a project or by the user. Being able to process several materials, they can never be a product to regret after buying. They should be bought from reliable places that not just provide for great products but also provide time to time services at the time of need and therefore proving to be the best-fit investment.

Reference

*Image from https://cncmachines.com/