CNC milling is not a difficult concept to comprehend if you are well acquainted with the concept of “Milling” in the first place. The very abbreviation “CNC Milling” stands for Computerized Numerical Control Milling. So, while milling looks into the process of material cutting by putting rotary cutters into use, CNC milling only make the process a little more systematic by adding a computerized touch. Thus, CNC milling brings in computer controls in order to the simple machining process. This intervention carries with it several advantages. The very first and easily comprehendible advantage is that of easy handling and quick machining. Unlike simple milling that would require immense human attention and tact, CNC milling makes the machining process quite simple.

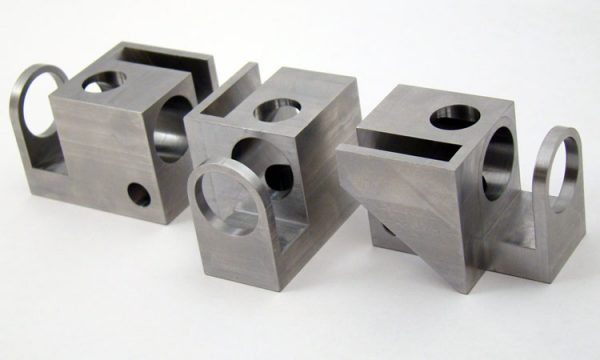

CNC milling parts*

In case any confusion clouds your mind regarding this particular process. Here are some of the most basic questions revolving around CNC milling that will help you understand the process better.

How do CNC Milling Machines Work?

CNC milling machines work with advanced computer controls and use rotary cutters to cut the undesirable parts/material from the work piece. This leaves only the desired product or product part behind. This is how the process helps us make custom products or parts with ease. After the initiation of the process, the rotary cutters work at the speed of more than a thousand rotations per minute and shape the work piece according to the fed design.

The products or product parts made can be successfully altered under basic capabilities. Thus, they can easily be physically, chemically, thermally, mechanically and electrically altered with utmost precision down to every single detail.

Which Materials can be Machined through this Process?

When it comes to CNC milling, a notable factor is that it can be used to machine a great range of products. Materials such as wood, glass, steel, plastic and several other metals can be turned into customized designs using this process.

What can CNC Milling do for you?

Once you understand the basics of the process, it isn’t difficult to analyze what can this process help you with. Similar to CNC machining, CNC milling can help you with basic processes with include the making of a CAD model, the conversion of a CAD model into a successful CNC program, the simple milling or products, as well as setting up the milling machine.

However, in any case the first process is the creation of a design. This design can be either a 2D or a 3D design of a CAD part. CNC milling then helps you achieve this design easily and within a stipulated time period through the enhanced computer controls.

To sum it all up, several requisite attributes can be attached to CNC milling. The designed products show great attention to complex details due to high machine accuracy. To add to the benefits, constant change of set up can also be kept at bay by bringing CNC milling into play. Above all, safety remains uncompromised and production volume reaches a noticeable high.

Reference

*Image from https://www.klhindustries.com/