Before you dive into the topic of plastic injection and how it works, here is something which you have to know. The definition of the said matter. The injection molding which happens to have for the fast process and is used for the production of the large and the identical items from huge and a precised list. There are thermoplastics that are used in the way, and they are the common materials that are managed out from the said work. Here are some of the elements which are used for the whole job.

- The Nylon PA which is used for the whole molding process.

- The polycarbonate molding which is used on the PC.

- The polypropylene is used as the PP.

How do they term out to be?

For all the plastic injection molding, which takes place, there is significance in the proportion of work that is used over time. These are the products which are managed out from the micro parts to the significant components and rightly on time and in the selective nature.

These are the rituality of the sectors of the manufacturing process and in the injected molded parts which are taken into the right lead and action. The flexibility in the size and the shape for the possible outcome of work are managed too.

The size and the shape and everything which is considered right on time will help in the mechanism of the boundaries of the design in plastics and enable all the significance mechanisms and the traditional materials which are done on the lightweight capacity and the design freedom too. These are the ways through which the plastic injection molding is taken into account, and the whole work is done on the basis of the said.

How does the whole work take place?

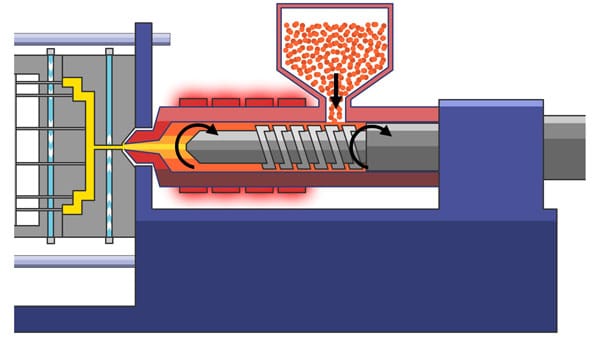

There are material granules which are used for the whole work before they’re fed via the help of a hopper. Then the hoper is carried down to the heated barrel, and then there are the melted beads that are worked out with the help of the heater bands. Plastic injection molding is then managed for the right source of work and in the frictional action for a reciprocating service, which is done on the intent of the screw and the barrel technique. The plastic is then injected directly into the mold to form the whole structure.

Then the product which is designed is done on the basis of the industrial designer and the help of their expert opinion. First, they have a look at the module which is out there for work and then takes the same on the basic structure and support too. These are the primary mechanism which is worked out for the whole source of time, and then the construction is managed out for the same. These leading framework of the line helps in the constructed line of work for the complete taken service, which is hopped into the same usage. These are mainly for the industrial function, which is carried out.

Reference

*Image from https://www.aireplastics.com/