CNC machining commonly stands for “computer numerical control”, in lay man’s terms it’s software that is used to control and manipulate the movement of machines and tools.

Whether you are a serious manufacturer or you are an enthusiast creating parts and products for your consumption, you need to know everything about the machining tools so as you can be better equipped to take full advantage of them.

For this post, we are going to have a detailed and in-depth discussion about everything you need to know about CNC machining cutting tools.

Different variations of CNC machines

Five different types of CNC devices are customized to perform different operations. They are of the following 5 categories-

Vertical CNC Milling Tools*

CNC Milling machine

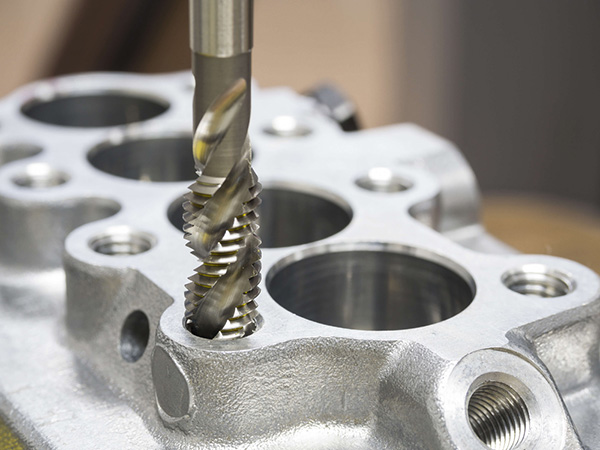

It is one of the most widely used machines that is monitored and operated by CNC technology. The technique used is quite similar to cutting and drilling, for its operation, the milling machine employs a rotational cylindrical cutting tool

Lathe machines

These machines are normally used to drill and shape pieces of metal, bore openings, cut threads, just to mention a few. Lathe machines work by removing the exterior layer of metal in the form of chips with the assistance of the tool

On the other hand, a CNC turning is another type of lathe which performs numerous drilling and milling operations and also acts as a valuable material for other purposes as well as manufacturing

Router machine

This is the most common type of CNC tool; the router machine is normally used without the assistance of human input and is operated independently by computers. The router machines are specially created for cutting hard materials such as wood, plastic, sheet metal, and foams.

CNC plasma cutter

This is another important type of CNC machining that’s normally used for cutting materials such as sheet metal, metal plates, bolts, pipes just to name a few

It integrates the power of electricity with gases like industrial air or nitrogen, argon, oxygen. Which comes with a high force and pressure through a constricted opening. The force exerted is in turn used to ultimatelycut through heavy metals with so much ease.

CNC laser cutter

A CNC laser cutter is very similar to a plasma cutter. The laser cutter uses a high force laser in place of plasma.

So, lets briefly look at some of the benefits that you should expect from using CNC machining tools

- Precision- The CNC machining tools work with a high degree of precision leaving no room for human errors. It provides accuracy levels of up to 1000 times making it suitable for large-scale manufacturing. It also significantly reduces dependency on human labor-saving you a lot of time

- Reduce cost- CNC machining tools cut down production expenses and cost due to traits such as efficiency and precision which improves the status of the company as they will be able to meet all the deadlines

- Efficiency- These machining tools have high efficiency due to the use of modern and advanced software. The machines can carve metals of every size, shape, and texture.

The modern CNC machines have made the work of designers and engineers fast, smooth ad seamless. Through these machines, a lot of new areas especially when it comes to innovation start opening up presenting new benefits to manufacturers.

Reference

*Image from https://www.serralaser.com/