Vacuum casting is a game-changing technology in manufacturing, also known as urethane or polyurethane casting. This process is more versatile than injection moulding and CNC machining, with several advantages. It is used in many industries such as automotive, aerospace, medical, consumer products, and electronics.

What’s Vacuum casting?

The process of vacuum casting involves utilising a vacuum to suck liquid material into a mould. The process begins with the creation of a master pattern from a part that has been 3D printed or CNC machined. In a pressurised environment, a silicone mould can be created using the pattern. After the mould has been prepared, pour polyurethane resin into it and then apply suction. The use of vacuum to remove air bubbles and guarantee a uniform distribution of casting material throughout the mould is essential. After the silicone has hardened, the mould must be removed and the finished product thoroughly cleaned.

Uses of Vacuum casting

Vacuum casting is versatile and produces high-quality parts with complex geometries, making it popular in many industries. Common applications include:

- It is great for making functional prototypes fast and cheaply. The process creates many design iterations quickly, so engineers and designers can test and refine ideas before full-scale production.

- It is great for low-volume production without high upfront costs of injection moulding or CNC machining.

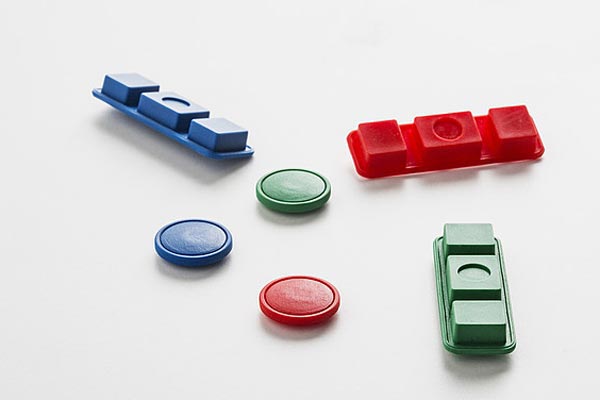

- It can create over molded parts with a rigid plastic part and a softer, flexible material. This process creates grips, seals, or gaskets for products.

- It is ideal for making medical devices and components because some polyurethane resins are biocompatible. It creates precise medical parts with complex designs.

- It is used in auto and aerospace to make strong, light parts. This process creates complex parts that are hard to make with traditional methods.

- It is used to make consumer products, including electronics and household items. It’s a cost-effective way to produce durable, high-quality goods.

Advantages of Vacuum casting

- It produces high-quality parts with excellent surface finishes and intricate details. Vacuuming removes air bubbles and ensures even filling for defect-free parts.

- It is cost-effective for prototyping and low-volume production. This process is affordable and suitable for startups and smaller companies with limited budgets as it doesn’t need expensive tooling or machinery.

- It is fast, with parts produced in days. It helps companies launch products faster and respond better to customer needs.

- It enables production of complex parts with intricate geometries not achievable by traditional methods. Designers have more freedom to create unique products.

- It works with many materials, including polyurethane resins that can be chosen for specific needs like strength or flexibility.

- It reduces waste by reusing silicone moulds and recycling excess casting material.

In comparison to more conventional production techniques, vacuum casting offers significant advantages in terms of both quality and cost. It is becoming increasingly important in the manufacturing industry, with applications in a variety of fields including medical, consumer goods, aerospace, and automobiles. It makes it possible for businesses to generate creative and high-quality goods in a more expedient and effective manner.

Image from https://www.1zu1prototypen.com/