Sheet metal is one of the foremost flexible materials in adornment making. Whether you’re making bangles, shaping your claim rings, or planning pendants, sheet metal is extraordinary for all sorts of adornments. But with so numerous diverse choices to select from, how can you tell which one is right for your venture? Do you get it completely tempered? And which thickness is best? Don’t stress. The article will guide you through everything you wish to know on how to work with sheet metal for adornments making ventures.

Crucial Sheet Metal Tools:

Smooth jaw pliers, flush cutters, calipers, repousse hammer, rawhide mallet, mandrel set, bench block, needle files, jewelers saw blades, and frame. Some other tools may include sanding pads, center punch, professional tools, drill bits, finishing wax, bench peg.

How Bending Can Affect Your Sheet Metal Project?

There are many ways you’ll control sheet metal. Whether that’s with a doming apparatus or a rawhide mallet, it works. Let’s say you need to form a band ring: the two key sheet metal devices you’ll require for this are a rawhide hammer and a mandrel. Essentially put the strip of sheet metal on the mandrel and pound at each point where it isn’t touching the mandrel. Keeping the straight end horizontal, proceed to move the metal forward over the mandrel until you’ve got bowed a third – at that point turn around and wrap up off the other end. You’ll moreover utilize a metal shaping device like a doming dapping set. With this pack, you’ll rapidly change the shape of a pendant into a domed shape – although it does work best with gentler metals.

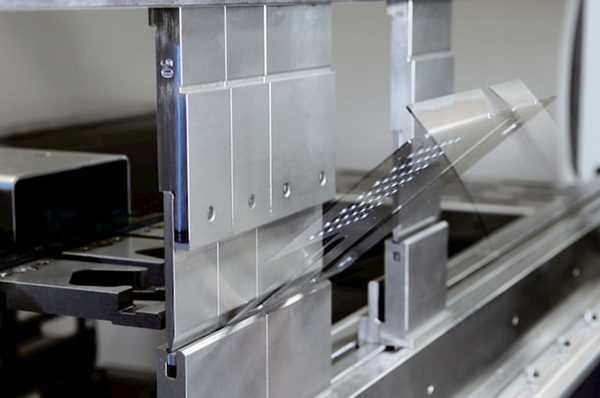

Sheet-metal-bending*

Cutting A Sheet Metal Material:

To begin, you’ll know how to cut sheet metal in case you need to utilize it in your plans. And there are two strategies – cutting with a jeweler’s saw or cutting with a Dremel device. On the off chance that you need to begin by employing a saw, make a stamp where you need to begin with a cut and outline out the rest of the shape. Begin slowly, and make your cut by making a little score at the beginning with, and after that slowly building up a weight to cut the rest of the shape. Does the edge keep getting stuck? Utilize a few oils to ease it up once more. Or if you’re as of now a pro with a jeweler’s saw, why not utilize your proficient instruments? It speeds up the method so you’ll center on wrapping up your plans to the most elevated conceivable standard.

Texturing In Metal Sheet Projects:

Somebody who works with sheets of metal will know that one of the most excellent ways you’ll be able to utilize the fabric is by texturing it. For a real natural, normal see, attempt making a patina with liver of Sulphur. Otherwise, you can make surface by making spaces within the metal and you’ll do this by as of now utilizing the devices in your workshop. For case, over and over striking the metal with the level edge of a jeweler’s pound makes a straight impact, idealize for more rectangular or square plans. Another well-known strategy is utilizing the adjusted edge of a repousse pound to make a gentler, pounded impact.

Reference

*Image from https://fractory.com/