CNC machining is an accessible process in the manufacturing industry for its variety of benefits. Using a computer to control the machine components, this is a tried and tested method used by many industries every single day. Almost everything that requires planned design or engineering turns to CNC machining services because all businesses and industries need quantities of large and small parts for their products.

Even the device you are reading this article from has a component created by CNC machining service. Your car or any machines you have in your garage has parts produced through CNC machining. What started as a simple manufacturing solution in the 1960s has become encompass almost the majority of applications in metal fabrication.

CNC Machining Defined

Before we discuss the benefits of CNC machining, let first define this manufacturing process for you to understand how it works. It used a computer-numerical control machine to operate the machine parts including the lathes, grinders, routers, mills, shapers, and many others. It means that these tools are controlled by the computer instead of being operated by humans.

When you compare CNC machining with manual operations, CNC machining is a lot faster and more precise, optimizing the level of production because it can do multitasking. By multitasking, it means that multiple axes are working on the material to accomplish the jobs.

If you are wondering what the computer in CNC machines looks like, they are not your typical desktop computer. The brains of the CNC machine are encased in a console and is programmed with “G-code,” a code written solely for CNC machining. This code has the elements that will enable to control over the feed rate, speed, coordination, and the position. With these codes, precise parts are produced which end up as the product itself or the building blocks of a product.

The process of CNC machining involves precise and high-speed movements to enable the machine to accelerate the production and customization and gain the benefits. CNC machining services include the job of the routers, mills, lathes, and grinders. It also involves forming, bending, tuning, and many other processes.

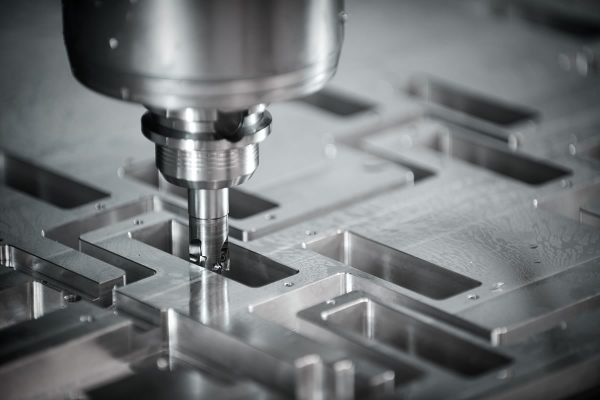

CNC milling machines*

Applications of CNC Machining Services

There are endless applications that use CNC machining using various kinds of materials like aluminum, stainless steel, carbon, brass, titanium, castings, wood, plastic, silver, gold and many synthetic materials like polycarbonate, ABS, among others. It can cater to a variety of orders like tiny metal plates bent to a specific angle, engraved with numbers or a large panel with a punched hole.

If a product needs fitting, bushings, manifolds, dies, molds, fixtures, and several components, CNC machining service can service all of them. CNC machining does not only function in all types of environments, but it can also help enhance the overall bottom line of the business by hastening the process in a clean and precise over other manufacturing methods.

Other applications of CNC machining include multiple axes machining, where objects are created from a solid piece of metal instead of needing to cast the material when you use the traditional method.

Benefits from Using CNC Machining

The CNC machining process is very straightforward. Using computer-aided design software to produce a three-dimensional model of what would be the final component. This model can be input in the system to set the machining and start creating the replica of the model. Once a template is completed and fed into the system, the parts are produced repeatedly.

CNC machining is used mostly in producing complicated 3D shapes. For businesses who are looking to save on their production, it is the best method to make sure that the products are delivered within the timeline.

Here are the benefits of using CNC machining.

Affordable price

One of the benefits of using this manufacturing method is that there is a minimum cost involved. Through CNC machining, they can have custom metal parts at a lower price.

Reduction in the production time

One of the essential benefits of CNC machining is the reduction in the production time. Spending more time on finding the right machined parts is counterproductive. Opting for CNC machining can take the specification and produce the unique parts required. Using a strong material will also ensure the durability of the manufactured parts.

Accuracy

Another advantage of using CNC machining is the products and parts produced are incredibly accurate. Many industries require highly specific parts, and this method is the answer. Using CNC machining will also provide accurate parts consistently many times over using the same machine.

Tight tolerance

Many accurate pieces require high tolerance to manufacture, which is a critical component in many industries. Customers can take advantage of using CNC machines to produce these parts, especially when a particular degree of tolerance is needed.

Some people have mourned the loss of manual milling and lathing techniques. However, these techniques can still flourish outside of the high-volume manufacturing environment. The growth of CNC machining, in exchange, have paved the way for the growth of new industries.

Refefence

*Image from on http://canwilleng.co.za