Manufacturing processes were borne out of necessity. For these companies, meeting the expectations of the clients while delivering quality parts depends on the use of sophisticated and collaborative machines.

One of these manufacturing processes is CNC machining. This technique has made a difference in producing parts with high precision in a short time and less cost. The CNC machine started as simple machines meant to cut down the time to create a part with more precision. However, due to the demand, technology has helped the process to meet these demands.

CNC machining is a digitized system that forms machine parts with the highest level of efficiency. Being one of the transformative technologies, it has also witnessed various innovations in the CNC machines in recent years.

Here are some of the innovations in the CNC machining industry.

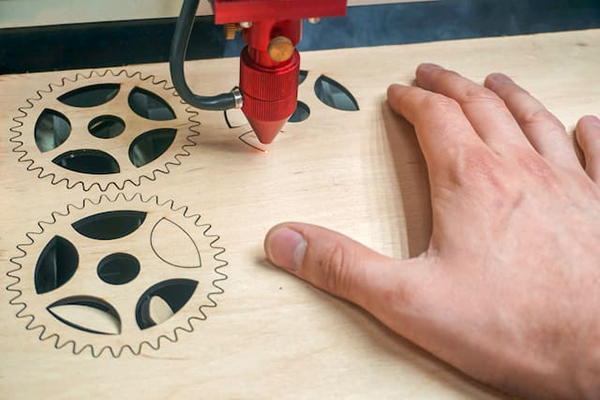

1. Use of Plywood in Laser Cutting

The man had been using wood as a building material since the dawn of history. And there are plenty of reasons why. Apart from being easily accessible, it is also strong and durable. But there is one property of wood that people are not so familiar with, flexibility.

The innovative CNC laser cutter has allowed manufacturers to take advantage of this property. With the CNC machining, it is now possible to create geometric patterns and etch designs on wood. It maintains the durability, sturdiness, and flexibility of the milled wood. Machined wood has plenty of applications ranging from decorative pieces to wall art.

Laser cutting wood*

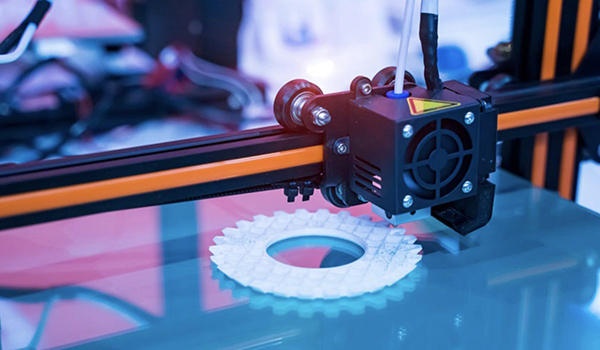

2. BoXYZ

3D printing and CNC machining are two different manufacturing methods. The former is an additive process, while the latter is the opposite. They have functioned independently and have their applications. Recent developments, however, have combined the two technologies into a single machine called BoXYZ. This machine is becoming popular because it has a CNC mill, laser engraver, and a 3D printer in one. It can cut the cost of machine investment.

3D printing manfacturing**

3.Machining Ice

The CNC machining process has a lot of applications and uses a wide range of materials from plastic to plexiglass to plywood. What if I tell you that there is another material where the CNC machine has not cut before? Ice. It may sound surprising, but it can cut ice. That is the magnitude of the improvement in the CNC machine.

In Japan, ice cubes are replaced by miniature ice masterpieces. Thanks to CNC machines, they can create intricate ice sculptures by converting vector information into G-code to mill the ice. It provides a new way to express creativity.

Finishing touches are applied to the temple shaped ice***

4. Machine Alerts on Smartphones

Everything is going mobile, and CNC machining is not left far behind. The latest innovation in CNC machining now includes alerts on your mobile devices. The newly developed automation process has allowed users to connect as many machines as possible in one system that will notify the users through email or phone about the status of the machine. Another innovation is the addition of a user-friendly interface for users to understand and know how to operate the machine.

CNC machines are everywhere. You can find them in large manufacturing firms and small and medium industry workshops. They are versatile and efficient machines that continue to evolve as demand continues.

Reference

*Image from https://fractory.com/

**Image from https://asiatimes.com/

***Image from https://www.designboom.com/