Modern manufacturing has evolved to levels that could not have been imagined 20 years ago. The 21st century pushed the boundaries of creativity when it came to creating products from the ground up. These days we can have production runs that are limited just to our budgets and imaginations.

Computer numerical control is the technology that allowed this to happen, and the creation of prototypes is crucial to make an idea come to life. Long gone are the days when the tooling of a prototype cost thousands of dollars, taking up a massive chunk of the budget. Now you can create a fully functional prototype of anything with prototype machining.

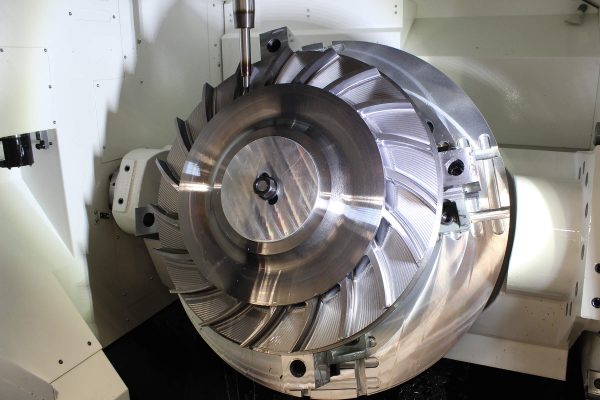

5 axis CNC machining*

The Contributions of Prototype Machining

If we need to explain in laymen’s terms what prototype machining is, we could say that it’s the procedure that allows us to create a product from scratch with specs that will match the finished product. Prototype machining is a bit more expensive than your average 3D printed prototype, usually created using a mixture of resins. Machined prototypes are made with state of the art technology using the actual materials used on your product.

If you are wondering what all of this brings to the table in terms of practicality, let us highlight the benefits for you:

Promptness

By creating your prototype with material akin to the finished product, you’ll be able to catch all the specs that could cause hold up at any stage. Time is always of the essence when you create a product with a very narrow window of opportunity in certain markets. Using prototype machining, you can calculate the time I’ll take to get a production run made.

Quality Control

By creating your prototype with this technique, you’ll get full insight into your product: how it looks like, the final measurements, the functionality, and everything related to data that can help you win over your competition. These prototype test trials can resist the same rigors as the actual finished product that will reach your potential consumers. You’ll have a positive advantage when it comes to retooling or upgrades to your design.

Cost and Value

Prototype machining can give you factual insight into the hard numbers that will cost your product’s creation. Many of the materials used in modern manufacturing have low costs, but their tooling is different. These specs can alter your budget. By trying out different materials, you will know what suits you best and what it’s more affordable for your customers in the long run.

Manufacturing Procedures to Spare

Prototype machining allows for different types of manufacturing. The most well-known are additive manufacturing and subtractive manufacturing. Both have their benefits and setbacks. The most notable feature is that your prototype will prove to be sturdier depending on your chosen technique. You must know the key difference between them and which one suits best to your finished product.

Reference

*Image from https://get-it-made.co.uk/