The manufacturing industry is working non-stop to find the right techniques in delivering parts and products to the consumers. One of these technologies is die-casting.

The die casting process is emerging as one of the top options in producing parts because of its significant advantages. It is touted as one of the most cost-effective solutions, particularly when you are working with complicated geometries. Die-casting can achieve tight tolerances and create unique parts without plenty of machining needed.

The dies can produce simple and complex parts. As the parts become more complicated and more expensive, this is the same for all manufacturing techniques. The advantage of die casting over other manufacturing techniques, however, is it can form a part with a single shot within milliseconds of injecting the material.

Aside from this advantage, this article explores the other benefits of die casting and why you should consider this manufacturing technique for your next project.

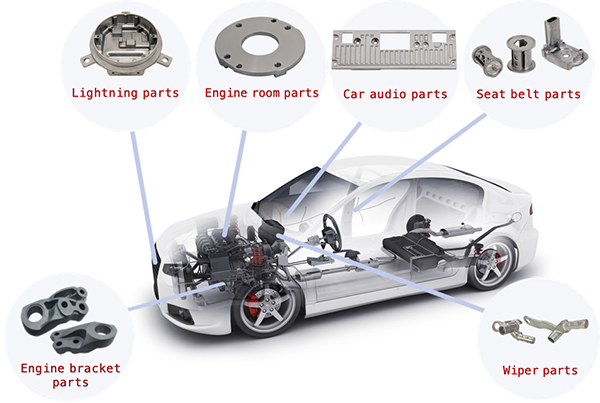

Aluminum die casting auto parts*

Advantages of Die-Casting

There are numerous benefits in manufacturing parts using die casting. We have enumerated only the top five that tends to be more favorable here.

The simplicity of the process

The die casting process involves simple and straightforward processes. It even allows fastening elements like studs and bosses to be incorporated into the design and be part of the casting process at no extra cost. With this unique design, the assembly would be faster.

Speed

Another benefit of using the die casting method is its speed. Die casting is one of the fastest production techniques. It allows producing parts in quick succession, even with complex geometries and shapes, without necessary machining. It also means that you can create thousands of parts without any additional tooling needed. This is a perfect technique for high-volume manufacturing.

Flexibility

Die casting allows for more flexibility than any other method. This flexibility is not applicable in the quantities to be produced at once but also in its finishes. With die casting, you can add textures, coatings, or finishes after the casting process is done.

Strength

Another reason to choose the die casting process is the strength of its finished parts. You cannot get this from the injection molding process. Although the die-casting products have the same dimensional support, it is stronger even with lighter or thinner walls. The strength is due to the part being in one piece that gives the internal support and structure.

Stability

Die casting products are also stable and have high heat tolerance. This has been a concern for many manufacturers who need to maintain high tolerance and dimensional stability on their products. Thanks to the die casting process. It can provide this requirement without any additional process required.

Key Takeaway

Choosing die casting as a manufacturing technique depends on the requirements. If your part has complex designs and you need to manufacture them in large volume, die casting is a good option. But if you only need to manufacture a few pieces, the cost of tooling would be high, and it is not a smart decision.

Reference

*Image from https://www.pegasus.co.jp/