CNC machining is one of the most important tools of the trade that you can learn and become conversant in this day and age. In the age where most college degrees and diplomas are becoming more and more obsolete, having hands-on skills will go a long way in ensuring you take your craft to the next level.

Being a certified and licensed CNC machinist is not difficult, it’s a simple and straightforward process. But, just like any discipline, it requires extensive practice. A lot of people actually get scared off as a result of the technical jargon and other challenges such as learning the properties of a wide variety of materials that you’ll be interacting with as well as basic coding.

Everything about CNC machining becomes easier if you put the work into practice. CNC machining is quite profitable in the current machining world as more people CNC machinist who will take their craft to the next level.

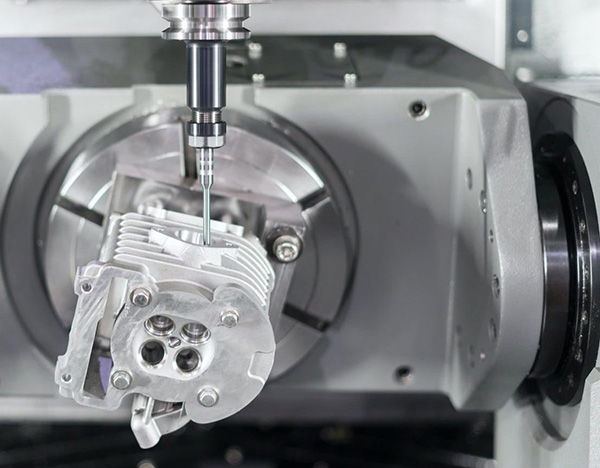

5 axis cnc machining*

Choosing a field as a machinist

There is a wide variety of fields as a machinist that you can choose when it comes to working as an operator. Generally, CNC machining is viewed as a full discipline, one can decide to learn about the whole field at one go to have all the skills that your potential employer might require.

Having a full skill set is also vital as it can assist you in set-up your very own workshop in the future if that’s something that you would like to pursue. For those who love specializing in one aspect, you can choose one CNC machining field to get your career off the ground allowing you to fully execute all the knowledge and expertise that you’ve learned.

Some of the most popular options that you can choose include:

G-Code developer

G-code is the central language that’s mostly used in CNC machines, this particular programming language is solely used to develop algorithms that will enable most CNC workshops to design the most complex and intricate designs.

For most workshops, they have their in-house G-code developers whose sole purpose is to code and ensure clients get the specifications and designs right.

CAM/CAD developer

CAM and CAD are amongst one the leading software that makes the layout and any part or product created using the CNC tech. All of the finished blueprints of any product and part is normally designed using these programs which are in turn fed onto the CNC machines the created the part using the axis/blade equipment in the workshop.

The first training as a developer in this particular aspect is to have all the design notions in the back of your mind. Another vital feature is to know the dialect of engineers, as it offers a lot of technical details that will be factored into the final detail.

Machining

This is a physical aspect of the job; you’ll need to converse yourself with it to get the first-hand experience. For most of the time, you’ll be working with materials, routers, drills, mills to get things done around the workshop to get your job done.

Reference

*Image from https://get-it-made.co.uk/