It’s one of the most sort processes in the manufacturing industry and will continue to remain so. The real question here is that, will people continue to adopt this procedure? With vacuum casting, getting rid of liquid from the molding compartment has been easy. Vacuuming has been a method that experts use to resolve entrapment issues in the past.

Whether it’s hand problems and understand, vacuuming works. Vacuuming is a process that helps in reinforcing fibers to make them better and work well. With thermoforming, industrial workers make out the best from their prototype jobs. If you want to ensure the preheat state of plastics, vacuuming can help. A glimpse into this manufacturing method tells you more of its importance.

Is Vacuum Casting Working Well For Industrial Professionals?

The advantages of this manufacturing process are what it takes to know how experts feel. It helps to deliver a quick and fast solution in the production of parts and products. When experts use this production style, it helps to deliver more products and parts. Another thing about this process is the top-notch products and parts it helps to produce.

If you are looking to design high-quality products, using this approach will help. Remember that using this strategy will not lead to consuming time during production. Getting adaptable and flexible results is one of the best reasons to use this method. While it’s not expensive to set up, accuracy will always be your end result.

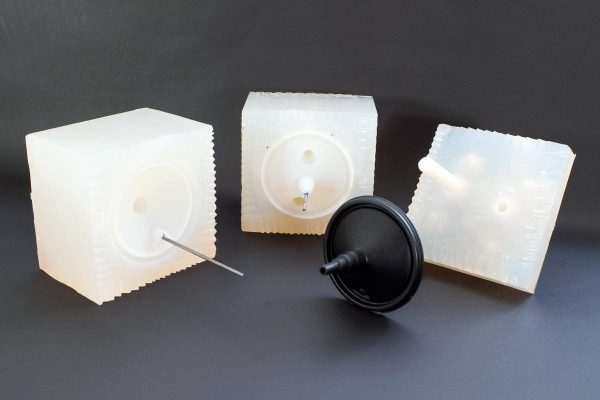

vacuum casting products*

How Does The Vacuum Machine Operates?

There is no universal way of using a vacuum machine. Every industrial expert can create a unique way of using this machine. When applying this production technology, most experts ensure to use 3D. With 3D designs, it’s easier to make use of vacuuming models to get top-notch results. Another thing to know is the maintenance process to ensure swift delivery. Once you are able to master these steps, using a vacuum machine remains simple.

What Are The Uses Of Vacuum Casting?

The use of this production procedure is more than most people think. In the creation of commercial & industrial products, it’s possible to use this method. In the healthcare sector, this method can help in the design of domestic products. Even with food, drinks, plastics, bottles, and tins, it’s a production process to use.

Facts Behind The Use Of This Manufacturing Method:

One thing is clear, using vacuuming, it delivers extraordinary results. It’s a unique practice that helps in the design of innovative parts and products. With this process, making your product reliable, efficient, and better remains possible. Another crucial fact to know that the process is cheap to set up. Most industries are now using this model to create products that can last for a long time. With these simple facts, people can start believing in what they can get from this process.

Summary:

The response to the question in this article remains yes. People will continue using this production method because it works. Since innovations occur, it means that this production method updates and evaluates. With this idea, you’re able to get a better result when using vacuuming for your everyday job.

Reference

*Image from https://dienamics.com.au/