Rapid prototyping is a technique for delivering user-centered content quickly and accurately. It does so by mimicking human interaction, with the content driven by a combination of modelling and testing. The key to rapid prototyping is in the process of learning through testing. Making a physical model of a fresh product design idea is known as rapid prototyping. This is carried out as a preliminary step before actual production and is most helpful when confirming that the finished product will have the desired appearance, feel, and functionality. For a variety of reasons, new product developers use fast prototyping. They serve as a bridge to low-volume manufacturing and are used for functional testing, approvals, design revisions, crowdfunding campaigns, and trade show models.

Rapid prototyping enables users to quickly generate a prototype of a new idea or product.

CNC machining

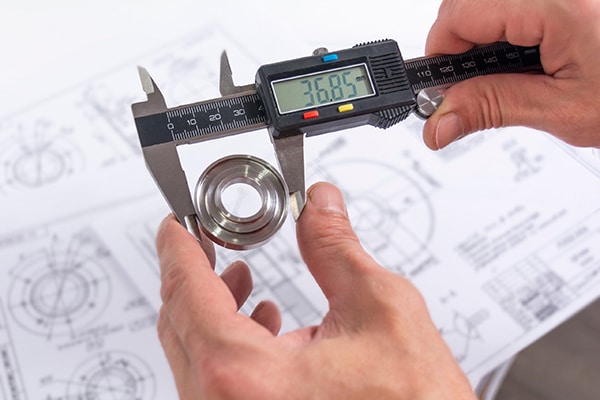

Making high-fidelity, end-use prototypes from a variety of raw materials is quite easy with CNC machining. It is adaptable, quick, and accurate. In order to improve the final output, it is very simple to make little adjustments to the cutting software. Additionally, CNC machining can create tapped and threaded holes, which is not possible using conventional techniques. Prototypes made with CNC machines are fully strong, making them appropriate for engineering testing.

Rapid prototyping services are currently on the market. They provide us with quick and cheap way of creating prototypes for our ideas, designs, applications and systems. The process is very simple; to get started you just need a 3D printer or a CAD software for creating CAD models of your product. Once you have created the prototypes, you can upload them to a service such as Shipwire or Foundry 3000, which will then create digital versions of your product from scratch.

Some companies use it when they want to prototype something without wasting time on soldering and designing everything from scratch.

tolerance of machining part

Vacuum casting

Online rapid prototyping services like SegoR and Canva allow designers to prototype and validate their designs. From your original master pattern, polyurethane vacuum casting moulds can produce up to 30 high-quality replicas. Engineering grade plastics and other resins can be used to mould parts, and they can even be overmolding with various materials. Due to its suitability for producing small quantities of hollow cases and enclosures, vacuum casting is frequently utilised as an alternative to plastic injection moulding.

We are masters at creating cast copies from master patterns in production quality.

You will profit from our extraordinary attention to detail in addition to the fact that we offer a full range of finishing services to upgrade your item to showroom condition. Find out more about the benefits of using our vacuum casting service.

Rapid tooling

These companies have been helping clients with product development and analysis. Rapid prototyping services help clients to quickly take a design decision and begin product development, with the aim of bringing tangible results to their clients’ attention.

With the help of our quick tooling service, you may get high-quality plastic injection mould tools in as little as two weeks. Rapid tooling can be the answer if you require prototype cases and enclosures for your project.

Reference

*Image from https://anttrom.com/