We are at a time of rapid technological advancement, yet manufacturers remain constrained with three factors: speed, quality, and cost. To achieve the right balance, you need to find the right manufacturing method. The good news is you can achieve them with 3D printing.

Throughout its 30-year history, 3D printing, with the help of digital technologies, is now used by some manufacturers to manufacture production parts, fixtures, and tooling, repairs, and even bridge production. Additive manufacturing, what 3D printing is known is gaining traction in large volume productions.

The recent advancements in 3D printing have revolutionized manufacturing. Here are some of the reasons why.

Improvement in Quality

The machine reliability and print quality of 3D printers have significantly improved in the last few years. It means that this method can now create improved parts with excellent quality surface finish and dimensional accuracy.

The improvements in material, on the platform, and the software solutions have enabled 3D printing to overcome its weaknesses before and that includes issues with machine repeatability. Because of this, it has reduced the amount of time and financial investment that is associated with setting up with new market demands.

Advancement in Speed

3D printing, when combined with intelligent digital advancements, enabled the global design team to work together on new designs virtually. Compared with having a physical representation of the product, this saves time spent from idea to prototyping to production. It brings manufacturing of a part of the product even closer to the consumer.

When you compare this with piloting a product in a more conventional manner, meaning the investments in tooling, equipment, and launching a pilot product, you can see that the advantages of 3D printing are more compelling.

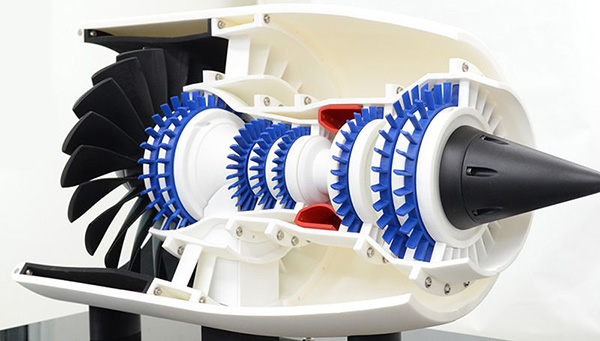

3D printing in aviation industry*

Cost Savings

Additive manufacturing needs fewer materials. Thus, it eliminates the need to build up an inventory. Because more manufacturers are using this manufacturing process, it has driven down the prices of these materials.

Another cost-benefit of 3D printing is it allows the building of highly complex parts with the use of a single machine. Manufacturing parts in one centralized location is also eliminated and instead, a part of all of the manufacturing process can be distributed locally. It makes it even closer to the user markets, thereby reducing transportation and warehousing costs.

Issues on Massive Talent Gap

Earlier we mentioned three variables that manufacturers are keeping in line: speed, quality, and costs. The fourth missing piece is talent. Today, the manufacturing industry is inundated with a huge talent gap. Additive manufacturing, however, has no shortage of real skills yet.

There is a prevailing need for manufacturing experts in 3D printing to assist in the maturing in the use of the tool to meet the strictest production requirements.

Customization and Additive Manufacturing

Perhaps the key contribution of additive manufacturing is revolutionizing the industry is its ability to serve in large-scale customization. The future of manufacturing is geared towards connecting directly with the consumers.

As we have witnessed in the Amazon effect that has disrupted the retail industry, additive manufacturing is also doing the same. It helps improve the consumer experience when it can provide better performance when products need to be customized.

Conclusion

Experts predict that additive manufacturing will have more impact in the years to come. It will go mainstream in a big way and as a manufacturer, you should be harnessing the pace and power of 3D printing manufacturing.

Reference

*Image from https://www.whiteclouds.com/