Whether it is about the best finishing options or the highest level of reproduction accuracy, the vacuum casting will always be a good choice. In the recent past time, most of the manufacturing businesses have started using the vacuum casting to generate prototypes and parts that have various advantages. By using this procedure, it is possible to improve the overall production quality in a whole new way.

When it comes to the product turnaround, the vacuum casting again becomes better. In easy words the vacuum casting ensures a prompt and fast product turnaround. In addition, it is possible to craft some parts and prototypes in unusual shapes. In addition to manufacturing the prototypes in unusual shapes, vacuum casting is beneficial for small wall thicknesses.

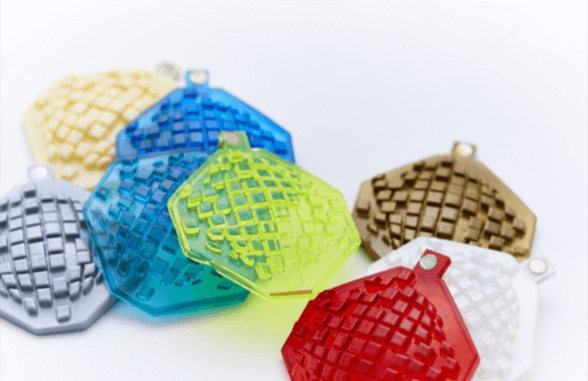

Vacuum casting molds*

In comparison to the vacuum casting, other methods and techniques will struggle to deal with these wall thickness and unusual shapes. If you are looking to have the short run batches, then vacuum casting is an affordable alternative.

Creation of plastic prototype parts

For the creation or manufacturing of plastic prototype parts, the vacuum casting process will always be required. It improves the quality and performance of the plastic prototype parts once it gets set.

Automotive parts

In order to make some automotive parts, the vacuum casting will again become a leading methodology or technique. Automotive parts need a little bit more accuracy and uniqueness then other products. All the desired changes can easily be crafted with the help of the vacuum casting in a very short time.

Commercial & home products

You should also know that the vacuum casting is a magnificent process for the creation of decorative object prototypes. Despite making the prototypes of commercial products, vacuum casting makes sure that manufacturers produce better prototypes of home products. In the category of decorative objects, you can count the short run custom ornaments as well as the wall plaques.

Product marketing

Among the most important applications of the vacuum casting, product marketing is the one we need to know more. In easy words, product marketing ensures that the launching of your new products will be a good and assuring experience.

Cosmetic products

You can see the use of vacuum casting prototype parts. In the manufacturing of the cosmetic products, vacuum casting helps by creating suitable prototype parts without any kind of doubt.

Mobile cases

Furthermore, you need to fit in your brain that the vacuum casting can help to prepare the prototype parts of mobile cases. This is another innovative application of the vacuum casting that perhaps you do not know till now.

Packaging final products

For the packaging of the final products that you want to launch into the market, you must prefer the vacuum casting than other methods.

Foods & beverages

The vacuum casting again becomes a dependable choice for the packaging of food and drink products that you see in the market.

Now, you have successfully become familiar with some incredible applications and uses of the vacuum casting procedure. So, take your time and have the rest of the benefits with this process.

Reference

*Image from https://kk-inac-us.com/