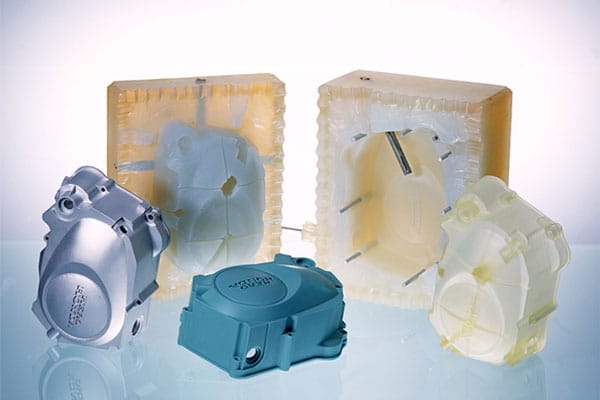

Vacuum casting is a highly versatile manufacturing process used to produce high-quality plastic, rubber or composite parts, primarily for prototyping, low-volume production and specialized applications. Vacuum casting is evolving through advances in materials, automation and hybrid manufacturing techniques as industries demand faster, more sustainable and higher performance solutions.

This article explores the key trends shaping the future of vacuum casting with a focus on material innovations, digital integration, sustainability and emerging applications.

Material Innovations Driving Vacuum Casting Forward

Materials are at the core of vacuum casting’s evolution, with new resins and composites expanding its capabilities beyond prototyping into functional end-use parts.

High-Performance & Engineering-Grade Resins

ABS-like, PP-like, and PC-like resins – Widely used for automotive, consumer goods, and electronics housings.

High-temperature resins (120°C+) – For under-the-hood automotive and aerospace components.

Flexible & rubber-like materials (TPU/TPE) – Ideal for seals, grips, and wearable devices.

Flame-retardant (UL94 V-0) resins – Critical for EV battery components and aviation.

Sustainable & Bio-Based Materials

Bio-derived resins (castor oil-based polyurethanes).

Recyclable & biodegradable formulations – Reducing environmental footprint.

Low-VOC & non-toxic materials – Safer for workers and compliant with regulations.

Composite-Enhanced Resins

Glass/carbon fiber reinforcements – For stiffness and strength.

Nanomaterials (graphene, CNTs) – Enabling conductivity and EMI shielding.

Mineral fillers (talc, ceramics) – Improving thermal stability.

Medical & Biocompatible Materials

ISO 10993-certified resins – For skin-contact and short-term implantable devices.

Dental & prosthetic-grade materials – High-detail, sterilizable castings.

Conductive & Functional Materials

Electrically conductive resins – For sensors, RFID, and embedded electronics.

Static-dissipative & EMI-shielding – For aerospace and electronics enclosures.

Thermally conductive resins – For heat sinks and LED housings.

Technological Advancements & Automation

Digital Integration & Smart Manufacturing

AI & machine learning – Optimizing mold design, material selection, and curing parameters.

IoT & real-time monitoring – tracking temperature, pressure and curing for consistency.

Automated demolding & post-processing – Robotics reducing labor costs.

Faster & More Precise Tooling

3D-printed master patterns (SLA, SLS) – Accelerating mold production.

Multi-cavity molding-increases batch efficiency without mass loss.

Hybrid Manufacturing Approaches

Vacuum casting + 3D printing – Combining cast parts with printed components.

Overmolding & multi-material casting – Complex parts with varying hardness/colors.

Expanding Industry Applications

- Automotive & Aerospace – lightweight, durable components for electric vehicles and drones.

- Medical & Dental – Custom prosthetics, surgical tools, and biocompatible prototypes.

- Consumer Electronics – Soft-touch housing, functional prototype with embedded electronics.

- Industrial & Energy – Flame-retardant and heat-resistant components.

Sustainability & the Circular Economy

Reusable & recyclable molds – Extending silicone mold lifespan.

Low-waste processes – Optimizing material usage and reducing energy consumption.

Closed-loop recycling – Reclaiming and reusing excess resins.

Challenges & Limitations

Not cost-effective for mass production – still best for low to medium volumes.

Material limitations – Some high-performance plastics (PEEK) remain difficult to cast.

Skill dependency – requires expertise in mold making and process control.

Conclusion:

The future of vacuum casting lies in:

✔ Smarter, automated processes (AI, IoT, robotics).

✔ Advanced materials (high-performance, sustainable, functional).

✔ Broader industry adoption (medical, automotive, electronics).

While vacuum casting cannot compete with injection molding for high volume production, it will continue to play a vital role in rapid prototyping, custom components, and small-to-medium batch manufacturing across a diverse range of industries. Its unique advantages in flexibility, cost-effectiveness for low volumes, and ability to produce high-quality, complex components ensure its enduring relevance in product development and specialized manufacturing applications.

Reference

*Image from https://www.scott-am.com/