The dynamics of any business especially manufacturing have truly shifted, the market is now competitive more than ever; either you shape up or ship out is the motto. Having a great or excellent idea does not cut it anymore, what’s needed now is faster delivery of product into the market to ensure there is no shortage which can quickly lead to loss of clients due to slow delivery.

We can’t blame capitalism or changing trends in technology, but the fact remains the same; if you have quality products chances are most people are going to buy them. One of the key challenges that most businesses face is, a majority of them want to offer high-quality products at great prices, but this usually comes at a cost.

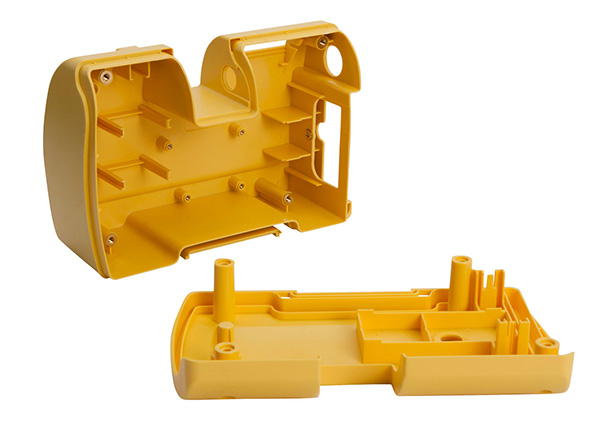

The manufacturing technique that you use will ultimately influence the quality of your product, but for those working with plastic there is only one technique that is superior to the rest and that is plastic injection molding.

Top secrets of selling plastic molded products in a competitive market

When you are in the business of manufacturing plastic products that are sold directly to the consumers, the workshop or the firm that you decide to go with plays a key role in the success of your project.

In all honesty, not all products do sell at key events such as Black Friday, this is usually the best opportunity of getting rid of all the old stock before new ones come in. The manufacturer can play a big part in meeting all the demands of your clients:

plastic parts*

Good logistics

If you’ve already chosen a manufacturer, you’ll need to cover a lot of basics most of which you’ll not have decided to factor in when coming up with the project. The first being the delivery of ideas for them to work on.

If your design is created using the CAD tech, the manufacturer should be able to work around that format regardless of the intricacies and complexities of your project. For those who have a rough sketch, that should be enough to work with.

Once production is finished, the manufacturer should be able to ship to your desired location. This will boost your brand visibility due to excellent logistics

Workshops that use the latest tech

This might be cliche, but it couldn’t be any further from the truth, those with the best capabilities are the ones who are most likely to cater to all of your needs. Using the latest tech and the best tools will result in minimal material wastage and they won’t deliver a faulty product.

Creation of huge volumes at incredible speeds

One of the most critical factors is the turnaround time of the manufacturer, time is of the essence so you’ll need an injection molding manufacturer who will get you high-quality products within the shortest time possible. With the right price, anything can be done in this world.

Reference

*Image from https://www.plunkettassociates.co.uk/