In cutting materials, CNC laser cutters often make use of a light beam to get the job done. These cutters also have the capability of cutting plastics, glass, wood, and sheet metal. In time past, machines often operate with a beam through mirrors on a lens. The entire process has changed because machines now make use of fiber optics. The fiber optics will help to melt or burn materials that will be used for production. When talking about laser cutting, you’ve to focus your mind on two methods. The ablative laser cutting and laser fusion cutting remains the two methods of this process.

Ablative Laser Cutting For Sheet Metal:

It’s one of the best methods that can help you create partial cuts in an item. Making partial cuts in the material these days may be a difficult task. On this note, the introduction of the ablative laser cutting method has helped to ease things a lot. Remember that it’s a cutting method that differs from using laser fusion cutters. The ablative laser cutting will not be able to handle tasks that need cutting through. When using the ablative laser cutting method, be prepared to spend more time in your work. It means that the ablative laser cutting process is time-consuming.

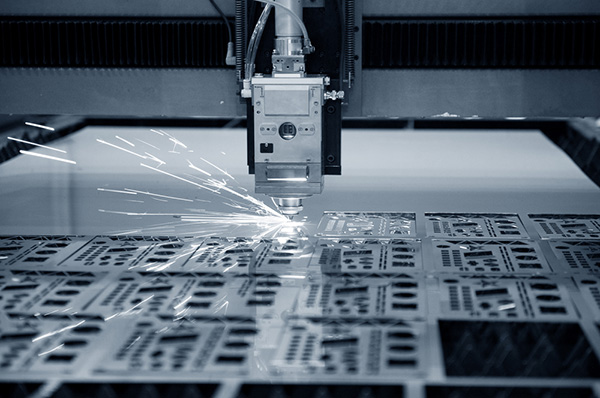

Laser cutting*

Laser Fusion Cutting:

With laser fusion cutting, you need argon or reactive nitrogen to enjoy the process. It involves cutting with the help of gas on the material to use. If you are working on thin sheet metal, then the laser fusion cutting process is the best. People that are envisaging a better appearance of machine parts can as well make use of this process. There is no further operation or processing needed when using laser fusion cutting on sheet metal. For instance, if you want to engage in grinding, it can help to unleash the best result. With the ablative laser cutting process, you’ll have to focus on material removal. The removal is also a process that occurs from one layer to another. It means thicker materials will suit the laser fusion cutting process better than others. With this simple explanation, it’s easy to see the differences between laser fusion and ablative cutting.

Advantages Of Fiber Laser Technology For Sheet Metal:

The fiber laser technology has been able to create more wonders in the production sector over time. Its application in machines gives way to produce quality parts and products. When in usage on sheet metals, it facilitates the quick production of parts and products. With fiber laser machines, you can get a better result than most equipment of the same category. In time past many people like using CO2 machines for cutting. Well, the truth is that fiber laser machines are now taking over the market. It implies that many people now find comfort in cutting metal sheets with fiber laser machines than before.

The reliability, confidence, creativity, and productivity of these machines is beyond anticipation. Besides, some people still like using the CO2 option even until now. It’s crucial to mention that fiber laser machines may not meet all the needs you want when cutting materials or parts. Depending on your need, it’s better to do thorough research before picking the right cutting machine. The options above can always serve you for a long with proper usage. The truth is that fiber laser technology will continue to gain more popularity in the production industry as long as it gives people quality and reliable results. The sheet metal industry is now encompassed by the ever-changing power of steel laser technology. It helps to achieve excellent repeatability and closer tolerance parts when using a reliable service provider.

The Essence Of The Most Common Laser Cutting Approaches:

CO2 and fiber are the most common approaches in this category. With the CO2 option, you will need helium, xenon, hydrogen, nitrogen, or carbon dioxide to stimulate the laser. In this process, the spark of activation will help the system work better than expected. With fiber lasers, you can make use of the optical beam structures such as dysprosium, neodymium, ytterbium, or erbium to activate the system. Before the creation of the laser fiber technology, people often follow one simple principle.

It states that the operational cost of the laser becomes lower when the wattage use is smaller. Today, this principle is no longer governing the operation of the laser fiber machine. It’s because fiber optics appear to be triple times faster and better than using the normal option. It is also a better way of achieving excellent repeatability and closer tolerance. Using the concept here will help you see the numerous advantages that fiber laser cutting has on sheet metals.

Reference

*Image from https://machiningservicesinc.com/