Are people still using the vacuum casting process these days? Why are most producers like vacuuming through casting to manufacture their products? Is this production procedure worth the time, money, and try? People that lack the knowledge of casting can make use of the questions above and gain something.

When talking about this manufacturing process, you have to follow some steps. The silicone cast has to get some resins through injection. Casting is a cheap production technique that can help with quality products. Another thing about this process is that it will not waste your time during production. When using this strategy, you can expect to get several benefits.

Using The Imperative Reasons For This Process:

When planning to engage in the packaging of parts and products, this process works well. It’s crucial to understand the reason for using this method before doing anything. In this section, you’ll discover some useful purpose for using the process here.

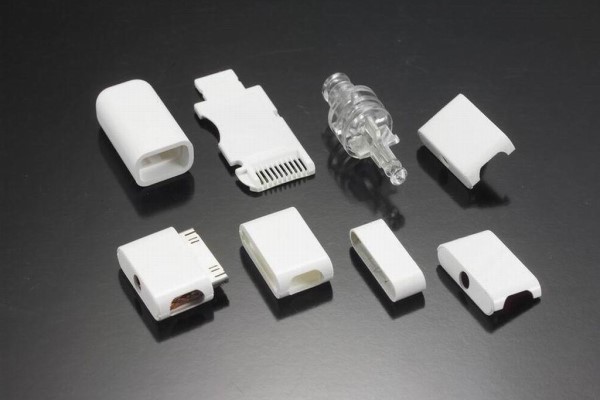

Vacuum casting services*

Reducing The Defects In Parts And Products:

When using this production method, people should focus on the reduction of risks. When gases are on the production process of parts and products, it can lead to damages. Using this production style can help get rid of risks that gas causes. With vacuum powder, you can get the defects out from your products or parts. Even with air pressure, this process helps you to achieve success without stress. With vacuum casting, it’s good that people can reduce any defect that may occur in the production of parts.

Improving Some Mechanical Features:

Improving some features is another reason people keep using this production method. The process helps to see mechanical features occurring during the manufacturing of parts. It’s a method that boosts the power of helping experts understand the process well.

Top-Notch Surface Finishing With Vacuum Casting:

The real purpose of using this process is to achieve top-notch surface finishing. The priority of this production process is to get a quality surface finish. With this, you’ll be able to work towards perfect during the production stage.

Improving Dimensional Precision:

The improvement that this process puts on the dimensional accuracy is beyond anticipation. With dimensional precision of parts and productions, you’ll always get better results. It helps your product display high performance in the market without much competition. On this note, professionals should ensure that it works with an accuracy of dimension.

Summary:

The casting & vacuuming process has been good for the reproduction of parts. People using this manufacturing process will always get better reproduction designs. One thing that the process gives is ensuring you see real improvement in products. Another thing to know is the short time that people can use in producing massive products and parts.

The improving performance of using the casting process is real and factual. If you’re looking for a production process that counts, then casting can help. Using this process has tons of benefits and usefulness for industrial professionals. Remember that it will also help in saving time, resources, and money. Boost your production performance today by using casting and vacuuming.

Reference

*Image from https://www.zeal3dprinting.com.au/