Getting your prototype ready lays the ground framework for testing your product to ensure that everything is ready and works properly as intended. A test run is vital as it showcases that all the components related to manufacturing and design are working properly as it should be.

Most of the big firms and companies have geared all their efforts in delivering the best product within a set budget; there are still challenges and barriers that can affect them. This is not an uncommon thing, for most rapid prototyping company; they need to work out a lot of details before delivery of a final product that is 100% viable and perfect that will meet the client’s expectations.

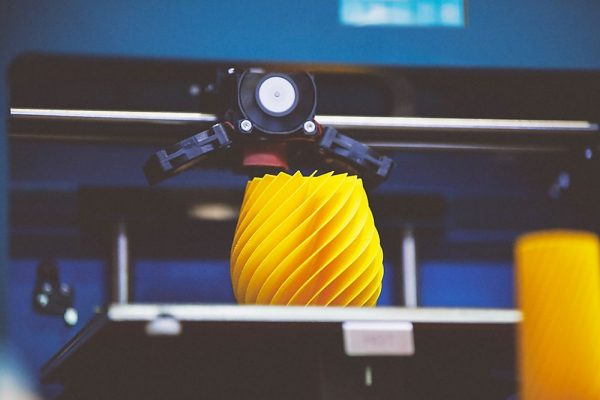

Finished products created from rapid prototyping or 3D printing will deliver the same level of functionality as finished products, but this will be wholly dependent on how the project was handled from the onset.

3D printing process*

It Begins with the Creation of a Prototype

Thanks to modern tech, entrepreneurs and business people have never had plenty of options to create anything they want. 3D printing has proven to be a key component in creating prototypes and parts.

When it comes to handy work, improvements have been made to standard tooling like plastic injection molding and vacuum casting making the whole procedure easy and seamless. These new improvements will enable companies to have the capacity to handle more volumes as well as small volumes from clients.

Raw Materials

The central role of a prototype is to perform the same task just as that of a finished product; the choice of the material used should be your top priority. The proof of concept should be affordable, but when it comes to a finished product, be ready to spend a little bit more.

However, the cost of producing a functional part will be just a tiny fraction compared to what it would have costed if you had opted for hand-tooling. For rapid prototyping companies, the total cost of materials can be a cause for concern, especially in modern tooling, as they have to be calibrated to work correctly together with other materials used in the product.

A look at the Final Details of the Finished Product

The finished product is regarded as the full spectrum of your project specifications: it can also be fully customized with the addition of colors, attention to detail with an elaborate finish. The effort and work that goes into this stage will determine the practicability of everything you want.

Most of our clients at LT Century prefer or pay special attention to detailed products which can be quite hard to market, especially if you aren’t an established brand. For brands like Apple or Samsung, they will not charge you $1500 just because their products look attractive, its because they invest a lot of time and effort to build their brands and churn out high-quality products that will stand out from the rest.

Reference

*Image from https://www.intechrp.com/